- Murphy DF755 Hydrostatic Head Level Switch

- MURPHY LEVEL SWITCHES

- The DF series are diaphragm-operated hydrostatic head pressure level switches. A pressure sensitive diaphragm operates a snap-switch that can be wired directly to electric pilot circuits to control pumps at predetermined levels. Typical application is to start and stop electric driven pump(s) to maintain tank levels. It is also applicable to engine-driven pumps. DF755 is suitable for atmospheric tanks in a non-hazardous area. The SPDT snap-switch for the DF755 is preset for a 4 in. (102 mm) differential in liquid level. Technical Data

- Read more

- Murphy BLS1 Level Switch

- MURPHY LEVEL SWITCHES

- Operates Bilge Pumps or Alarms. Uses Air Cell Actuated System. Remote Switch and Moving Parts Kept Unaffected by Corrosion Technical Data

- Read more

- Murphy LS200 Level Switch

- MURPHY LEVEL SWITCHES

- Murphy LS200 Level Switch Designed for harsh gas compressor scrubber applications, the LS200 Series Liquid Level Switches feature a robust design that trips on rising liquid level only. With both electric and pneumatic models available, the instruments screw directly into the vessel or can be mounted via an external float chamber. The nickel-plated body provides enhanced corrosion protection while the 304 stainless steel float operates in 0.55 specific gravity and heavier fluids. Additional features include: Rated for 2000 psi (13.8 MPa) [138 bar] working pressure Listed for Class I, Div. 1, Grp. C & D locations Canadian registered Stainless steel models available for corrosive atmospheres The LS200 Series replaces the FW Murphy Series L1200 Liquid Level Switches. The MSLS (Scrubber Level System) replaces the LS200 high-level shut-down switch with the MLS-020 magnetic level switch. Technical Data

- €538.17 (excl. VAT)

- Add to cart

- Murphy DVU Dump Valve

- MURPHY LEVEL SWITCHES

- For Separators/Scrubbers to 138 bar Working Pressure.Operates on 2.07–4.83 bar Control Pressure.Compatible With Murphy Level ControlsTechnical Data

- Read more

- FW Murphy LM500 Lube Level Maintainer

- MURPHY LEVEL SWITCHES

- The FW Murphy LM500 model maintains the crankcase oil level of an engine, pump or compressor. Adjusted to the correct running oil level, the LM500 will replenish oil as it is used. The low level switch will alarm and/or shut down the equipment if the supply oil is lost and the equipment continues to use oil.Direct Mount (DM) capableEliminates under/overfill due to “human error”See oil level and condition without shutting downSimple installationAutomatically maintains lube levelLow level, 3-wire, snap-action switchPositive sealing Thumb-Valve™

- €188.07 (excl. VAT)

- Add to cart

- FW Murphy LM500-TF

- MURPHY LEVEL SWITCHES

- The LM500-TF model includes a test feature that confirms both the float and switch are operating correctly with a single press of the test button. Direct Mount (DM) capable Eliminates under/overfill due to “human error” See oil level and condition without shutting down Simple installation Automatically maintains lube level Low level, 3-wire, snap-action switch Positive sealing Thumb-Valve™

- €212.00 (excl. VAT)

- Add to cart

- Pipe mount kit LM500

- MURPHY LEVEL SWITCHES

- €54.00 (excl. VAT)

- Add to cart

- Murphy L1100 Level Switch

- MURPHY LEVEL SWITCHES

- Replaced by LS200 These float operated level switches are available in electric and pneumatic models. They are primarily designed for high level applications but models are available for low level. Electric models are listed for Class I, Division 1, Groups C & D hazardous locations. Models are available in all stainless steel to NACE standard MR-01-75 for direct exposure to H2S service. These level switches have screw-in connections for direct installation or an optional external float chamber is available for the L1200 series high pressure versions. The high pressure versions of both L1100 and L1200 series are rated for 2000 psi (13,8 MPa) [138 bar] operating pressure. Designed for harsh gas compressor scrubber applications. More robust design. Technical Data

- Read more

- Murphy L1200 Level Switch

- MURPHY LEVEL SWITCHES

- Murphy L1200 Level Switch Replaced by LS200 These float operated level switches are available in electric and pneumatic models. They are primarily designed for high level applications but models are available for low level. Electric models are listed for Class I, Division 1, Groups C & D hazardous locations. Models are available in all stainless steel to NACE standard MR-01-75 for direct exposure to H2S service. These level switches have screw-in connections for direct installation or an optional external float chamber is available for the L1200 series high pressure versions. The high pressure versions of both L1100 and L1200 series are rated for 2000 psi (13,8 MPa) [138 bar] operating pressure. Designed for harsh gas compressor scrubber applications. More robust design. Technical Data

- Read more

- Bubble Lens for Murphy Level Maintainer LM300 Series

- MURPHY LEVEL SWITCHES

- This is the bubble lens component of the Murphy Level Maintainer LM300 Series. For information on Level maintainer LM300, click here.

- €49.00 (excl. VAT)

- Add to cart

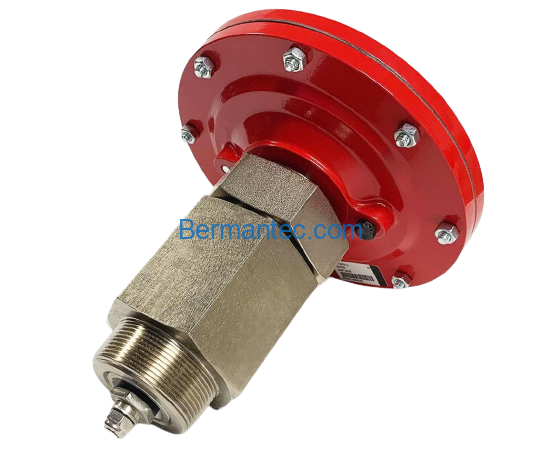

- Murphy Dump Valve DVU150

- MURPHY LEVEL SWITCHES

- MURPHY DVU150 1800 PSI (12.4 MPa)The DVU Series are pneumatically controlled dump valves. The valves open and close automatically by pneumatic control from a Murphy L1200NDVOR or similar Murphy level controller and dump valve operator.The DVU series dump valves operate at 30–70 psi (207–483 kPa) [2.07–4.83 bar] and up to 2000 psi (13.8 MPa) [138 bar] vessel pressure (depending on the model).A key benefit of this design is a hex union that provides the ability to replace the seat without removing the valve from piping. Body Material: Electroless Nickel Plated 12L14 Carbon Steel. Internal Wetted Parts:Plug Seal: 90 Durometer UrethaneOther: 303 stainless steel; Electroless Nickel Plated 12L14 Carbon Steel. Technical Data

- Read more

- Murphy Dump Valve DVU175

- MURPHY LEVEL SWITCHES

- MURPHY DVU175 1800 PSI (12.4 MPa)The DVU Series are pneumatically controlled dump valves. The valves open and close automatically by pneumatic control from a Murphy L1200NDVOR or similar Murphy level controller and dump valve operator.The DVU series dump valves operate at 30–70 psi (207–483 kPa) [2.07–4.83 bar] and up to 2000 psi (13.8 MPa) [138 bar] vessel pressure (depending on the model).A key benefit of this design is a hex union that provides the ability to replace the seat without removing the valve from piping. Body Material: Electroless Nickel Plated 12L14 Carbon Steel. Internal Wetted Parts:Plug Seal: 90 Durometer UrethaneOther: 303 stainless steel; Electroless Nickel Plated 12L14 Carbon Steel. Technical Data

- Read more

- Murphy Dump Valve DVU2105

- MURPHY LEVEL SWITCHES

- MURPHY DVU2105 500 PSI (12.4 MPa) The DVU Series are pneumatically controlled dump valves. The valves open and close automatically by pneumatic control from a Murphy L1200NDVOR or similar Murphy level controller and dump valve operator.The DVU series dump valves operate at 30–70 psi (207–483 kPa) [2.07–4.83 bar] and up to 2000 psi (13.8 MPa) [138 bar] vessel pressure (depending on the model).A key benefit of this design is a hex union that provides the ability to replace the seat without removing the valve from piping. Body Material: Electroless Nickel Plated 12L14 Carbon Steel. Internal Wetted Parts:Plug Seal: 90 Durometer UrethaneOther: 303 stainless steel; Electroless Nickel Plated 12L14 Carbon Steel. Technical Data

- Read more

- Murphy Dump Valve DVU2115

- MURPHY LEVEL SWITCHES

- MURPHY DVU2115 1500 PSI (10.3 MPa)The DVU Series are pneumatically controlled dump valves. The valves open and close automatically by pneumatic control from a Murphy L1200NDVOR or similar Murphy level controller and dump valve operator.The DVU series dump valves operate at 30–70 psi (207–483 kPa) [2.07–4.83 bar] and up to 2000 psi (13.8 MPa) [138 bar] vessel pressure (depending on the model).A key benefit of this design is a hex union that provides the ability to replace the seat without removing the valve from piping. Body Material: Electroless Nickel Plated 12L14 Carbon Steel. Internal Wetted Parts:Plug Seal: 90 Durometer UrethaneOther: 303 stainless steel; Electroless Nickel Plated 12L14 Carbon Steel. Technical Data

- Read more

- Murphy Dump Valve DVU2120

- MURPHY LEVEL SWITCHES

- MURPHY DVU2120 2000 PSI (13.8 MPa)The DVU Series are pneumatically controlled dump valves. The valves open and close automatically by pneumatic control from a Murphy L1200NDVOR or similar Murphy level controller and dump valve operator.The DVU series dump valves operate at 30–70 psi (207–483 kPa) [2.07–4.83 bar] and up to 2000 psi (13.8 MPa) [138 bar] vessel pressure (depending on the model).A key benefit of this design is a hex union that provides the ability to replace the seat without removing the valve from piping. Body Material: Electroless Nickel Plated 12L14 Carbon Steel. Internal Wetted Parts:Plug Seal: 90 Durometer UrethaneOther: 303 stainless steel; Electroless Nickel Plated 12L14 Carbon Steel. Technical Data

- Read more

- Murphy Level Maintainer LM302

- MURPHY LEVEL SWITCHES

- The LM302 Level Maintainer automatically adds oil to the crankcase as needed to keep the lube level normal. LM302 base model comes as a level maintainer with two switches for low and high level shutdown or alarm. Four wires, DPST, wired N.O. in normal operating ranges. Technical Data

- Read more

- Murphy Level Maintainer LM303

- MURPHY LEVEL SWITCHES

- The LM303 Level Maintainer automatically adds oil to the crankcase as needed to keep the lube level normal. LM303 base model comes as a level maintainer with two switches for low and high level shutdown or alarm. Four wires, DPST, wired N.C. in normal operating ranges. Technical Data

- Read more

- Murphy Level Maintainer LM304

- MURPHY LEVEL SWITCHES

- The LM304 Level Maintainer automatically adds oil to the crankcase as needed to keep the lube level normal. LM304 base model comes as a level maintainer with two switches. Alarm before shutdown on low level and shutdown on low-low level.Four wires, DPST, wired N.O. in normal operating ranges. Technical Data

- Read more

- Murphy Level Maintainer LM305

- MURPHY LEVEL SWITCHES

- The LM305 Level Maintainer automatically adds oil to the crankcase as needed to keep the lube level normal. LM305 base model comes as a level maintainer with two switches. Alarm before shutdown on low level and shutdown on low-low level. Four wires, DPST, wired N.C. in normal operating ranges. Technical Data

- Read more

- Isov Pneumatic Valve N200-P

- ISOV EMERGENCY SHUT OFF VALVES

- The Pneumatic ISOV valve N200-P is operated by applying Air or Oil pressure to the pneumatic cylinder integrated in the body. The Pressure inlet port is shown in the adjacent drawing. The pneumatic cylinder trips and closes ISOV when a pressure source is applied. The air or oil pressure is applied by using a 2/3 way solenoid valve as shown on the diagram. After tripping the pneumatic cylinder, ISOV will close and the 2/3 way solenoid has to be reset after which the valve can be opened and latched in the same manner as the Manual version. To increase safety, all ISOV pneumatic valves will be equipped with a manual Pull handle in case the solenoid for any reason may fail due to electric blackout. Standard Pressure inlet ports are 1/8 or 1/4 "size.

- Contact us to get your price

- ISOV Pneumatic Valve N400-P

- ISOV EMERGENCY SHUT OFF VALVES

- The Pneumatic ISOV valve N400-P is operated by applying Air or Oil pressure to the pneumatic cylinder integrated in the body. The Pressure inlet port is shown in the adjacent drawing. The pneumatic cylinder trips and closes ISOV when a pressure source is applied. The air or oil pressure is applied by using a 2/3 way solenoid valve as shown on the diagram. After tripping the pneumatic cylinder, ISOV will close and the 2/3 way solenoid has to be reset after which the valve can be opened and latched in the same manner as the Manual version. To increase safety, all ISOV pneumatic valves will be equipped with a manual Pull handle in case the solenoid for any reason may fail due to electric blackout. Standard Pressure inlet ports are 1/8 or 1/4 "size.

- Contact us to get your price

- ISOV Pneumatic Valve N600-P

- ISOV EMERGENCY SHUT OFF VALVES

- The Pneumatic ISOV valve N600-P is operated by applying Air or Oil pressure to the pneumatic cylinder integrated in the body. The Pressure inlet port is shown in the adjacent drawing. The pneumatic cylinder trips and closes ISOV when a pressure source is applied. The air or oil pressure is applied by using a 2/3 way solenoid valve as shown on the diagram. After tripping the pneumatic cylinder, ISOV will close and the 2/3 way solenoid has to be reset after which the valve can be opened and latched in the same manner as the Manual version. To increase safety, all ISOV pneumatic valves will be equipped with a manual Pull handle in case the solenoid for any reason may fail due to electric blackout. Standard Pressure inlet ports are 1/8 or 1/4 "size.

- Contact us to get your price

- ISOV Pneumatic Valve N800-P

- ISOV EMERGENCY SHUT OFF VALVES

- The Pneumatic ISOV valve N800-P is operated by applying Air or Oil pressure to the pneumatic cylinder integrated in the body. The Pressure inlet port is shown in the adjacent drawing. The pneumatic cylinder trips and closes ISOV when a pressure source is applied. The air or oil pressure is applied by using a 2/3 way solenoid valve as shown on the diagram. After tripping the pneumatic cylinder, ISOV will close and the 2/3 way solenoid has to be reset after which the valve can be opened and latched in the same manner as the Manual version. To increase safety, all ISOV pneumatic valves will be equipped with a manual Pull handle in case the solenoid for any reason may fail due to electric blackout. Standard Pressure inlet ports are 1/8 or 1/4 "size.

- Contact us to get your price

- ISOV Valve Pneumatic N1268

- ISOV EMERGENCY SHUT OFF VALVES

- The Pneumatic ISOV valve is operated by applying Air or Oil pressure to the pneumatic cylinder integrated in the body. The Pressure inlet port is shown in the adjacent drawing. The pneumatic cylinder trips and closes ISOV when a pressure source is applied. The air or oil pressure is applied by using a 2/3 way solenoid valve as shown on the diagram. After tripping the pneumatic cylinder, ISOV will close and the 2/3 way solenoid has to be reset after which the valve can be opened and latched in the same manner as the Manual version. To increase safety, all ISOV pneumatic valves will be equipped with a manual Pull handle in case the solenoid for any reason may fail due to electric blackout. Standard Pressure inlet ports are 1/8 or 1/4 "size.

- Contact us to get your price

- Isov Valve Electric N200-E

- ISOV EMERGENCY SHUT OFF VALVES

- ISOV Pneumatic Valve N200-E Equal to the P and M version, all ISOV E versions must be latched open by rotating the manual reset Hexagon as shown in the drawing(1). Once latched the reset lever will remain in the latched position until released by activating an linear 12 or 24 VDC solenoid(2). All ISOV solenoids are optimized to apply the right force to release and close ISOV, in this way a compact overall dimension can be guaranteed. Unlike other suppliers of safety valve all our Solenoids are equipped with an IP65 rated junction box which guarantees safe and reliable wiring required in the industry. Equal to the P version all E versions are equipped with the manual Pull Handle (see drawing) to increase safety in case electric power is lost.

- Contact us to get your price

- ISOV Electric Valve N400-E

- ISOV EMERGENCY SHUT OFF VALVES

- ISOV Pneumatic Valve N400-E Equal to the P and M version, all ISOV E versions must be latched open by rotating the manual reset Hexagon as shown in the drawing(1). Once latched the reset lever will remain in the latched position until released by activating an linear 12 or 24 VDC solenoid(2). All ISOV solenoids are optimized to apply the right force to release and close ISOV, in this way a compact overall dimension can be guaranteed. Unlike other suppliers of safety valve all our Solenoids are equipped with an IP65 rated junction box which guarantees safe and reliable wiring required in the industry. Equal to the P version all E versions are equipped with the manual Pull Handle (see drawing) to increase safety in case electric power is lost.

- Contact us to get your price

- ISOV Electric Valve N600-E

- ISOV EMERGENCY SHUT OFF VALVES

- ISOV Pneumatic Valve N600-E Equal to the P and M version, all ISOV E versions must be latched open by rotating the manual reset Hexagon as shown in the drawing(1). Once latched the reset lever will remain in the latched position until released by activating an linear 12 or 24 VDC solenoid(2). All ISOV solenoids are optimized to apply the right force to release and close ISOV, in this way a compact overall dimension can be guaranteed. Unlike other suppliers of safety valve all our Solenoids are equipped with an IP65 rated junction box which guarantees safe and reliable wiring required in the industry. Equal to the P version all E versions are equipped with the manual Pull Handle (see drawing) to increase safety in case electric power is lost.

- Contact us to get your price

- ISOV Electric Valve N800-E

- ISOV EMERGENCY SHUT OFF VALVES

- ISOV Pneumatic Valve N800-E Equal to the P and M version, all ISOV E versions must be latched open by rotating the manual reset Hexagon as shown in the drawing(1). Once latched the reset lever will remain in the latched position until released by activating an linear 12 or 24 VDC solenoid(2). All ISOV solenoids are optimized to apply the right force to release and close ISOV, in this way a compact overall dimension can be guaranteed. Unlike other suppliers of safety valve all our Solenoids are equipped with an IP65 rated junction box which guarantees safe and reliable wiring required in the industry. Equal to the P version all E versions are equipped with the manual Pull Handle (see drawing) to increase safety in case electric power is lost.

- Contact us to get your price

- Isov Failsafe Valve N200-FS

- ISOV EMERGENCY SHUT OFF VALVES

- ISOV Failsafe Valves are often used on offshore cranes as well as on Oil and Gas installations whereby the valve has to close whenever electric power is lost. The FS version requires Oil or Air pressure to guarantee its functionality. The basic working principle is that Pressure holds the valve open by energizing a 2/3 way Normally Closed solenoid valve. When power is lost the solenoid creates loss of pressure causing ISOV to trip and close.

- Contact us to get your price

- Isov Failsafe Valve N400-FS

- ISOV EMERGENCY SHUT OFF VALVES

- ISOV Failsafe Valves are often used on offshore cranes as well as on Oil and Gas installations whereby the valve has to close whenever electric power is lost. The FS version requires Oil or Air pressure to guarantee its functionality. The basic working principle is that Pressure holds the valve open by energizing a 2/3 way Normally Closed solenoid valve. When power is lost the solenoid creates loss of pressure causing ISOV to trip and close.

- Contact us to get your price

- Isov Failsafe Valve N600-FS

- ISOV EMERGENCY SHUT OFF VALVES

- ISOV Failsafe Valves are often used on offshore cranes as well as on Oil and Gas installations whereby the valve has to close whenever electric power is lost. The FS version requires Oil or Air pressure to guarantee its functionality. The basic working principle is that Pressure holds the valve open by energizing a 2/3 way Normally Closed solenoid valve. When power is lost the solenoid creates loss of pressure causing ISOV to trip and close.

- Contact us to get your price

- Isov Failsafe Valve N800-FS

- ISOV EMERGENCY SHUT OFF VALVES

- ISOV Failsafe Valves are often used on offshore cranes as well as on Oil and Gas installations whereby the valve has to close whenever electric power is lost. The FS version requires Oil or Air pressure to guarantee its functionality. The basic working principle is that Pressure holds the valve open by energizing a 2/3 way Normally Closed solenoid valve. When power is lost the solenoid creates loss of pressure causing ISOV to trip and close.

- Contact us to get your price

- Isov Remote Manual Valve N200-M

- ISOV EMERGENCY SHUT OFF VALVES

- Remote Manual Valve N200-M: The Manual Pull Kit consists of a special Bracket plus internals to be mounted on the ISOV valve and connected by a Cable to the Control Panel Knob which is positioned inside the operators cabin. This kit can be delivered in any length and the Manual Pull Kit can be equipped on all ISOV valves, regardless of ISOV bore size. The Remote Manual Pull Configuration is usually found on mobile equipment, trucks, small welding machines, gen-sets etc. ISOV emergency shutoff valves prevent enginge overspeeding by shutting off the air intake line. Prior to starting the engine the manual ISOV emergency vave must be latched open by rotating the manual reset axis (1) One latched the reset lever will remain in the latched open position untill released by pulling the manual trip handle(2). The manual trip handle can be mounted directly on the valve (see figure 1) or mounted remotely using a special kit which includes a pull cable, available in different lengths. The manual pull handle can be equipped on all ISOV valves, regardless of size.

- Contact us to get your price

- Isov Remote Manual Valve N400-M

- ISOV EMERGENCY SHUT OFF VALVES

- Remote Manual Valve N400-M: The Manual Pull Kit consists of a special Bracket plus internals to be mounted on the ISOV valve and connected by a Cable to the Control Panel Knob which is positioned inside the operators cabin. This kit can be delivered in any length and the Manual Pull Kit can be equipped on all ISOV valves, regardless of ISOV bore size. The Remote Manual Pull Configuration is usually found on mobile equipment, trucks, small welding machines, gen-sets etc. ISOV emergency shutoff valves prevent enginge overspeeding by shutting off the air intake line. Prior to starting the engine the manual ISOV emergency vave must be latched open by rotating the manual reset axis (1) One latched the reset lever will remain in the latched open position untill released by pulling the manual trip handle(2). The manual trip handle can be mounted directly on the valve (see figure 1) or mounted remotely using a special kit which includes a pull cable, available in different lengths. The manual pull handle can be equipped on all ISOV valves, regardless of size.

- Contact us to get your price

- Isov Remote Manual Valve N600-M

- ISOV EMERGENCY SHUT OFF VALVES

- Remote Manual Valve N600-M: The Manual Pull Kit consists of a special Bracket plus internals to be mounted on the ISOV valve and connected by a Cable to the Control Panel Knob which is positioned inside the operators cabin. This kit can be delivered in any length and the Manual Pull Kit can be equipped on all ISOV valves, regardless of ISOV bore size. The Remote Manual Pull Configuration is usually found on mobile equipment, trucks, small welding machines, gen-sets etc. ISOV emergency shutoff valves prevent enginge overspeeding by shutting off the air intake line. Prior to starting the engine the manual ISOV emergency vave must be latched open by rotating the manual reset axis (1) One latched the reset lever will remain in the latched open position untill released by pulling the manual trip handle(2). The manual trip handle can be mounted directly on the valve (see figure 1) or mounted remotely using a special kit which includes a pull cable, available in different lengths. The manual pull handle can be equipped on all ISOV valves, regardless of size.

- Contact us to get your price

- Isov Remote Manual Valve N800-M

- ISOV EMERGENCY SHUT OFF VALVES

- Remote Manual Valve N800-M: The Manual Pull Kit consists of a special Bracket plus internals to be mounted on the ISOV valve and connected by a Cable to the Control Panel Knob which is positioned inside the operators cabin. This kit can be delivered in any length and the Manual Pull Kit can be equipped on all ISOV valves, regardless of ISOV bore size. The Remote Manual Pull Configuration is usually found on mobile equipment, trucks, small welding machines, gen-sets etc. ISOV emergency shutoff valves prevent enginge overspeeding by shutting off the air intake line. Prior to starting the engine the manual ISOV emergency vave must be latched open by rotating the manual reset axis (1) One latched the reset lever will remain in the latched open position untill released by pulling the manual trip handle(2). The manual trip handle can be mounted directly on the valve (see figure 1) or mounted remotely using a special kit which includes a pull cable, available in different lengths. The manual pull handle can be equipped on all ISOV valves, regardless of size.

- Contact us to get your price

- Thermostatic Valves – Size: 3″

- THERMOSTATIC VALVES

- Multiple Flange Ratings. Housings: SS, DI, Br, Al. Pressure Rating: 19 BarTechnical Data

- Contact us to get your price

- Thermostatic Valves – Sizes: 2 1/2″

- THERMOSTATIC VALVES

- Multiple Flange Ratings. Wide Choice of Housing Materials. Pressure Rating: 19 BarTechnical Data

- Contact us to get your price

- Thermostatic Valves – Sizes: 1 1/2″ up to 2″

- THERMOSTATIC VALVES

- Used in Refrigeration Service. WCB-Steel Housing. Pressure Rating: 34.5 barTechnical Data

- Contact us to get your price

- Thermostatic Valves – Sizes: 3/4″, 1/2″ & 1″

- THERMOSTATIC VALVES

- Three Way Operation. Housing: SS, DI, Al, Br. Pressure Rating: 34.5 BarTechnical Data

- Contact us to get your price

- Thermostatic Valves – Sizes: 3/4″ & 1/2″

- THERMOSTATIC VALVES

- Two or Three Way Operation. Mounts in any Position. Housing: Aluminum or BronzeTechnical Data

- Contact us to get your price

- THERMOSTATIC VALVES – SIZE: 6″

- THERMOSTATIC VALVES

- 3 Way OperationHousing: SS, CS, CI, BrPressure Rating: 19 BarTechnical Data

- Contact us to get your price

- Valve SE101 1”NPT

- THERMOSTATIC VALVES

- Pipe size: 1''NPT92*95*153

- Contact us to get your price

- Valve SE111 3/4” NPT

- THERMOSTATIC VALVES

- Pipe size: 3/4'' NPT92*95*153

- Contact us to get your price

- Thermostat 2050-185

- THERMOSTATIC VALVES

- Contact us to get your price

- Thermostat 2050-120

- THERMOSTATIC VALVES

- Contact us to get your price

- Thermostat 1060-100 38°C

- THERMOSTATIC VALVES

- Contact us to get your price

Powered by Landholm.io